Contact Us

Any questions?

Fill in your contact information, we’ll contact you!

With a 100% Italian taste, New Marbas S.p.a offers collections able to satisfy the most demanding needs on the market. Every single garment originates from an in-depth analysis and interpretation of seasonal trends, enhancing the distinguishing features of each brand.

In addition to garments from our collections, we are able to offer our experience and professionalism to transform our customers’ ideas into knitwear. Our style department supports customers step by step, from the design of the first sample garment to the final production, searching for the best solution according to the various needs.

Thanks to our manufacturing plant operating in complete vertical integration, we are leaders in the textile field with private-label productions and with our brands.

In our hands the raw material is transformed, changed, and upgraded into a high quality fabric and finished garment.

The raw yarn is our starting point.

Thanks to the most sophisticated machinery and technologies, we carry out the weaving and dyeing of yarn and fabric. And this is only the beginning.

The fabrics are then mercerized and go through the finishing phases necessary to achieve the desired effect, satisfying even our customers’ personalised requests.

After being mercerized, the fabrics are checked 100% to ensure the highest level of quality.

If they pass this stage, the products are marketed with eventually matching collars, cuffs and and ribbing, or undergo the subsequent stages of cutting, sewing and ironing leading to the realization of the finished garment.

We are also prepared to follow, upon specific customer request, through all the logistical and packaging stages of the product.

From the idea to delivering the finished product, Marbas Group is at the customer’s side to meet all their needs.

We have always offered customers the possibility of “going inside the company” and getting involved with the realization of the product. This exchange of ideas, combined with the possibility of accessing and viewing the historical archive (composed of both finished garments and fabrics) allows designers and customers to find inspiration, starting points on which to build customised proposals.

Once the guidelines have been defined, we offer the possibility of producing, as quickly as possible, fabric swatches on small circular electronic machines to have a preview of the design mock-ups being studied.

After receiving and sending the specifications of the requested product to the patterns department, we are able to develop tailor-made patterns and create prototypes through our small internal production unit.

Using the expertise of our specialists, we evaluate the aspects inherent to production and finishing techniques, to transform the customer’s idea into fabric intended for a direct sale or the realization of finished products.

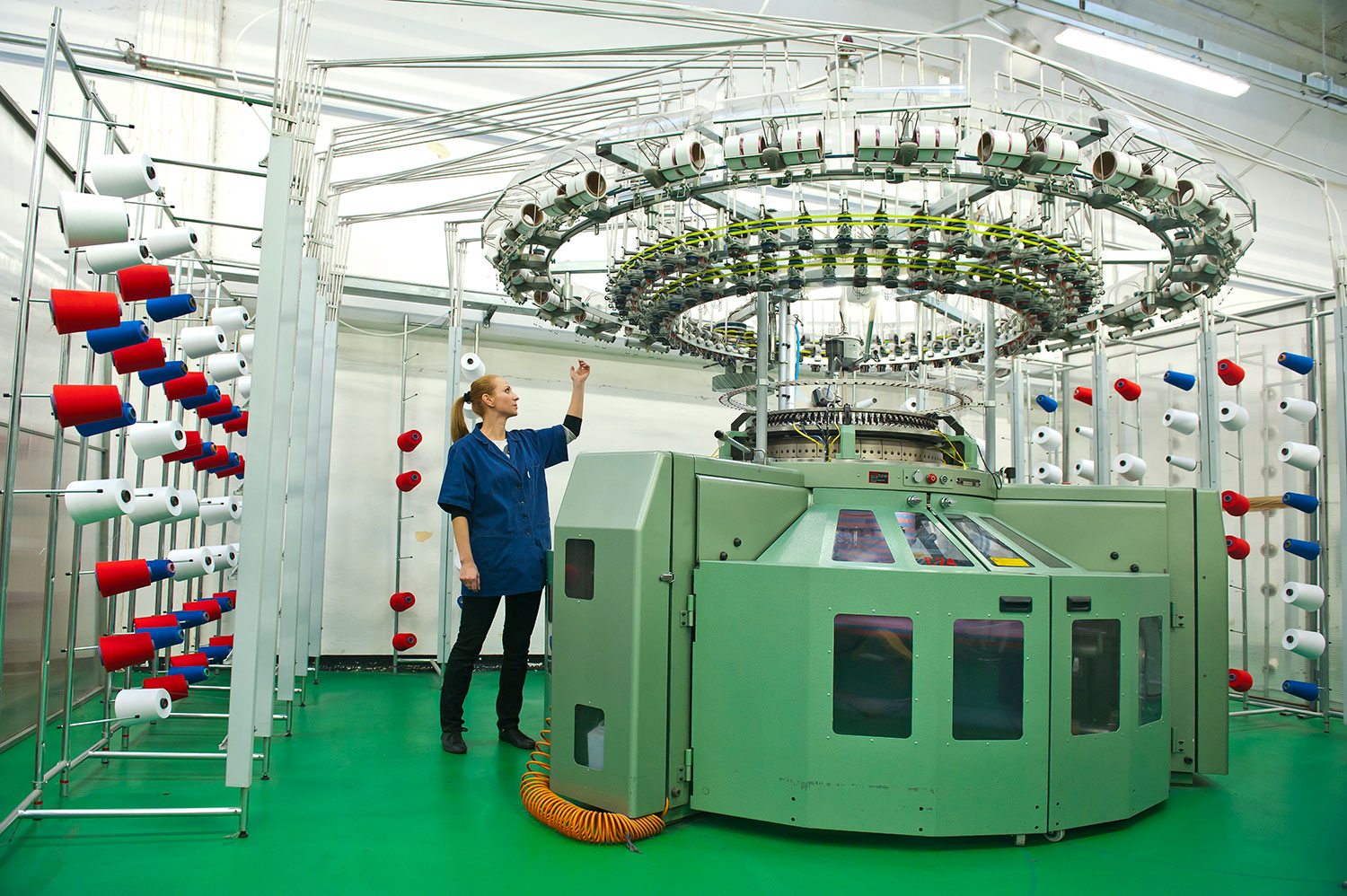

A large circular machine fleet allows us to produce the most varied types of knitted fabrics. Meticulous processing cycles and strict controls at all stages of the production process ensure the excellence of these products in order to respond to the high quality standards required by our customers.

Fill in your contact information, we’ll contact you!

Stai utilizzando un browser obsoleto.

Il seguente sito NON è ottimizzato per Internet Explorer.

A fatal exception IE has occurred at C0DE:L05TUD10 in 0xC0DEBA5E.

oppure clicca il pulsante qui sotto:

aggiorna il tuo browser!